CASE STUDY: air pollution control equipments plants

AIR POLLUTION CONTROL EQUIPMENTS DESIGN

BMB air pollution control equipments design is useful for Purification photocatalytic filters and can be applied to all cases in which odours and pollutants coming from vents in industrial production processes need to be treated. For instance, in case of vents installed on storage tanks for high odorous substances (leachates, chemical products, sewage ecc.). Read the case study and find out how work BMB Purification air pollution control equipments plants design.

CLIENT’S NEED

Air pollution control equipments design is necessary for odour pollutant substances (COT) containment

TECHNOLOGY EMPLOYED

Photocatalytic filtration

POLLUTANTS ABATEMENT

Odour removal efficiency ≥ 98%

COT abatement > 90%

STRENGTHS

High abatement performance

No electricity consumption

High energy saving

No environmental impact

AMONG OUR CLIENTS

THE CONTEXT: AIR POLLUTION CONTROL EQUIPMENTS

BMB Purification industrial photocatalytic filters , used in air pollution control equipment plants design, can be applied to all cases in which odours and pollutants coming from vents in industrial production processes need to be treated. For instance, in case of vents installed on storage tanks for high odorous substances (leachates, chemical products, sewage ecc.).

CHALLENGES

LOW ENVIRONMENTAL FOOTPRINT

Reduce odours and dangerous pollutants and obtain the maximum abatement of pollutants possible with minimum energy consumption. Employ technologies at low environmental footprint.

SOLUTION

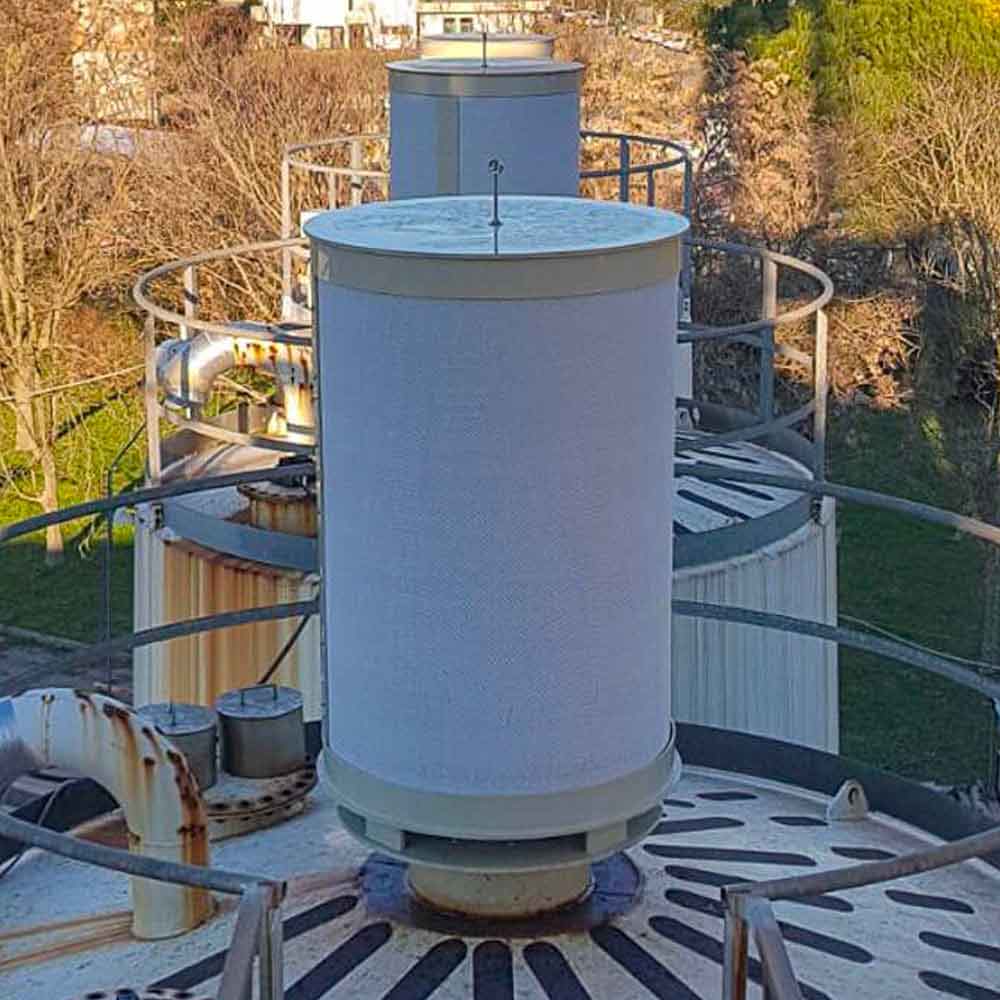

FILTERS ACTIVATED BY SUNLIGHT UV RADIATION

Each storage tank is equipped with its dedicated photocatalytic filter activated by sunlight UV radiation.

Filters are installed directly on the tank’s vent and allow both air outbreathing (tank loading) and inbreathing (tank emptying), working as relief and vacuum breaker valves.

TURNKEY PLANT

Each industrial air pollution control equipments plant realized by BMB is custom designed after thorough field study. The initial study of condition, context and potential problems allows or technicians to propose targeted and tailored solutions, appointed plants and specific technologies for any kind of problem.

MANUFACTORING AND INSTALLATION

Each plant produced by BMB is designed, built and tested in-house. The installation is planned and carried out by our specialized technicians.

MAINTENANCE ASSISTANCE

BMB offers complete and custom service for plant assistence and maintenance: oordinary maintenance, extraordinary availability and remote monitoring.

PLANT DESIGN

Our plants are designed in compliance with the most updated law and engineering standars, are applied to needs of client so as optimize the investment.

FAQs about air pollution control equipments plants

What are air pollution control equipments plants?

Air pollution control equipment plants are designed to treat odours and pollutants generated by industrial production processes, such as vents on storage tanks containing odorous substances like leachates or chemicals. They use photocatalytic filters activated by UV sunlight to efficiently remove pollutants, providing high abatement performance with no electricity consumption, resulting in energy savings and minimal environmental impact.

What are air pollution control equipments designed for?

Air pollution control equipment is designed to treat and reduce pollutants and odours generated by industrial processes, particularly from vents in storage tanks or production areas. These systems aim to purify the air by removing harmful substances like volatile organic compounds (VOCs) and other pollutants, improving air quality while minimizing environmental impact and energy consumption.

What are the benefits of using air pollution control equipments plants?

Air pollution control equipment plants efficiently remove pollutants like odours and VOCs, are energy-efficient, environmentally sustainable, low-maintenance, and help industries comply with air quality regulations.

Where are air pollution control equipments plants commonly used?

Air pollution control equipment plants are commonly used in industries like chemical processing, wastewater treatment, oil and gas, food production, and storage tanks, where odorous or harmful pollutants are released during production processes.